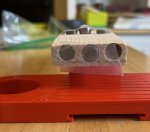

So I think I may have a problem with my son’s car and want to know if I need to redo the body before moving on to polishing the wheels and axles.

It is a 3 wheel rail-rider. Right now I have a COG of 1/2 in front of rear axle with 1.5 oz tungsten behind the rear axle and 2.0 ounces in front of rear axle. Will probably need to adjust weights slightly after painting, graphite, CA glue by axle holes, etc. and figure that will need to come from back due to the 1/2 COG. Didn’t measure weight distribution on wheels yet.

We don’t have a test track (I do have a 8 foot piece of plywood to set the steering. My 2 main concerns are :

1 - am I losing to much potential energy with 1.5 oz behind and 2.0 oz in front of axles?

2 - will the car be too wobbly and unstable with such a tight COG and the weight distribution behind/in front of axles? I think the extra weight in front actually helps here, right?

I obviously need to drill another row of holes in front of axles and my thought was to put more weight in the front 3 to shift the COG.

I know it is a less than ideal design but I am limited on tools and time since I will be out of town and the car has to be finished tomorrow. And we already bought cylinder weights before finding this site and learning about the cubes and ladder design. I do have tungsten putty and more of the smaller cylinders.

Sorry so many questions this week but first time building a thinner car and trying to account for all these new tips I am learning about!

It is a 3 wheel rail-rider. Right now I have a COG of 1/2 in front of rear axle with 1.5 oz tungsten behind the rear axle and 2.0 ounces in front of rear axle. Will probably need to adjust weights slightly after painting, graphite, CA glue by axle holes, etc. and figure that will need to come from back due to the 1/2 COG. Didn’t measure weight distribution on wheels yet.

We don’t have a test track (I do have a 8 foot piece of plywood to set the steering. My 2 main concerns are :

1 - am I losing to much potential energy with 1.5 oz behind and 2.0 oz in front of axles?

2 - will the car be too wobbly and unstable with such a tight COG and the weight distribution behind/in front of axles? I think the extra weight in front actually helps here, right?

I obviously need to drill another row of holes in front of axles and my thought was to put more weight in the front 3 to shift the COG.

I know it is a less than ideal design but I am limited on tools and time since I will be out of town and the car has to be finished tomorrow. And we already bought cylinder weights before finding this site and learning about the cubes and ladder design. I do have tungsten putty and more of the smaller cylinders.

Sorry so many questions this week but first time building a thinner car and trying to account for all these new tips I am learning about!

Attachments

Last edited: