When building my car I use a 1/4 basswood body. Rear wheels canted 3 degrees raised NDFW all drilled with the Silver Bullet. The problem I have had when drilling is that with a 1/4" body the lifted wheel bearing is high enough that it cuts a groove in the top of my body. So I have taken to getting a 1/32" strip of balsa and placing it under the front of my body when I drill the front axle holes to lower the holes just enough. However it's not there when I drill the rear axle holes. I have noticed that I get some wiggle in my cars after they leave the downhill run. Is it possible the 1/32" lowering of the front wheels is throwing my rear cant off just enough to cause this wiggle? If so will adding the 1/32" strip to the entire length drill jig correct it? Any help would be most welcome. Please and thank you.

Body drilling question

- Thread starter Dan Hodge

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

When building my car I use a 1/4 basswood body. Rear wheels canted 3 degrees raised NDFW all drilled with the Silver Bullet. The problem I have had when drilling is that with a 1/4" body the lifted wheel bearing is high enough that it cuts a groove in the top of my body. So I have taken to getting a 1/32" strip of balsa and placing it under the front of my body when I drill the front axle holes to lower the holes just enough. However it's not there when I drill the rear axle holes. I have noticed that I get some wiggle in my cars after they leave the downhill run. Is it possible the 1/32" lowering of the front wheels is throwing my rear cant off just enough to cause this wiggle? If so will adding the 1/32" strip to the entire length drill jig correct it? Any help would be most welcome. Please and thank you.

I’ll preface this by saying that I’m a beginner, but this is what I was told recently. I use the SBE to drill my holes. If the DFW axle is bent, and the NDFW axle isn’t, you don’t need to raise the hole for the NDFW. That bend in the DFW axle should be enough to lift the NDFW.

You are throwing off your alignment by shimming the front in the manner that you are. If you have enough of a bend on your DFW you shouldn't need to use the lifted wheel bushing.

Could be alot of other things causing the wiggle. If you post more details we could help you through it.

I have about 4” in 4’ of steer. https://photos.google.com/album/AF1QipMMrFwgVL4toV5uJVUDiwbN_U0IAuAql1W3sTYB

sorry for the link but having issues getting the photos to post right.

sorry for the link but having issues getting the photos to post right.

Most scout builds need more than 4 in over 4 feet because you are using smaller axles..unless you have some perfect wheels you will probably need 5 or 6 inches of streer and real tight gaps

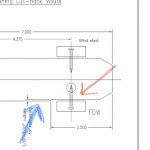

Again, I’m fairly new at this also, but it looks like your front wheels and rear wheels are an equal distance apart. I think that if you cut 1/16” off of the car body for your NDFW, that will help a lot. Looks like you cut a lot off (more than 1/16”), but you cut it off in front of the axle). Here’s a photo to illustrate. The axle should be moved 1/16” (red arrow). You have it where the blue arrow is. I think that makes a really big difference.

Attachments

Most scout builds need more than 4 in over 4 feet because you are using smaller axles..unless you have some perfect wheels you will probably need 5 or 6 inches of streer and real tight gaps

I agree ...the Cubs I help all are using the BSA axles with crimps. They normally need about 5" - 6" of steer. They are also using stock uncut wheels.

Similar threads

- Replies

- 4

- Views

- 586

- Replies

- 8

- Views

- 1K